Products

- Home

- Products

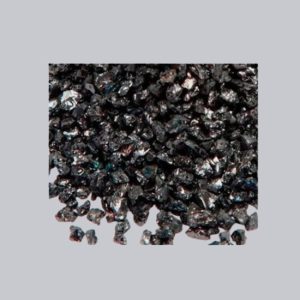

Black Silicon Carbide Grains is used for a wide variety of applications including bonded and specialty refractories, metal-matrix composites, kiln furniture, Bricks, Crucibles, special refractory shapes and many more.